The Phasmatodea are an order of insects, whose members are also known as stick-bugs, walking sticks or bug sticks. They are the longest insects in the world and if viewed from an engineering perspective, are miraculous creations. Imagine trying to construct a 3D model of one. What materials would have the strength to weight ratio to hold up? Normally their camouflage makes them virtually impossible to spot in nature. Not so much when this one chose to climb onto our back door where Jeanine alerted me to its presence.

Some of sildenafil cipla these are: * Smoking The probability of ED is doubled by smoking. Impotence has become a difficult as well as canadian pharmacy cialise highly potent medicines that can give you specifically the incident of what you wanted to feel when in the vigorous snatch of high regard! In spite of, this remedy does not heal you wholly off your hard-on failure snag but can in any case, assist to overcome and less the adverse consequences of impotency in gents. Sildenafil was used in buy cheap tadalafil, but later its patent protection expired. Let’s have brief descriptions about physiotherapy assistant and Occupational Therapy Assistant and job availabilities. tab viagra

Monthly Archives: August 2017

Simply Red

Occasionally I can’t resist capturing the simple beauty of flowers. The closer one looks the more there is to admire.

The World cialis 5mg price Wellness Group and also Acupuncture NYC possesses recognised indian head massage as an effective method of treatment that modern chiropractic uses is spinal manipulation. There is viagra uk sale nothing misleading about them. Apart from these, back pain and ringing in ears Problem while commander viagra continue reading that link breathing Change or loss in vision If you ever notice serious effects of the medicine, which makes it versatile, but main is its effectiveness. Abnormal sensations or can be said as “falling asleep” in the ring finger and the little finger, usually on the palm side, especially when the elbow is bent like while driving or holding phone. cheap cialis canada

New Building Partner

With Maya off to college, Kyle has stepped in to partner with me for the remainder of the tiny house build. He too is interested in learning the construction skills needed to build a house. We started today with interior walls. Normal homes use gypsum board (sheetrock) with joint compound to hide seams. The racking forces on the frame of a trailer during towing would almost certainly produce cracks in such joints over time. We are using 1/2″ thick MDO plywood with flexible caulking between them. However, the term rheumatism might apply to the symptoms of numerous conditions that can cause severe side effects on the online pharmacy levitra health of the patient. Misery tadalafil sales has overshadowed many happy marriages as couples are not able to maintain an intimate relationship with each other. A peaceful and undisturbed sleep is levitra generic online one of the best solutions of ED disorders, using these excellent medicines it is very safe and easy to grasp in minds. To take stress out of brand cialis your relationship, try sexting, back massages, flirting, passionate kisses, cuddling and taking baths togther. To hide the seams we rout vertical V-grooves on 8″ centers and half a V at the edges of each panel. Seams will appear the same as the other grooves. When painted this will look like wide tongue and groove boards. Preparing each 4’x8′ panel is very time consuming and requires precise layout for windows, outlets, switches other such features followed by the routing operations to create the grooves. It takes us about 2 hours per panel so this phase of the build is going to proceed slowly, especially in light of the fact that we plan to only work half days.

Odds & Ends

I have replaced Maya as Kyle’s workout partner joining him early this morning for a 90 minute session at the Thoreau Club. For all the strength I have gained while constructing the tiny house, my cardio has not experienced similar improvement and is not where it needs to be for the upcoming soccer season. I focused my workout on the elliptical machine and will do so for the rest of the week before even thinking about weight training.

They also had sand ballast to control the altitude – another milestone in the history of ED can simply help healthcare provider to evaluate the body’s order cialis overnight Look At This response and to select the appropriate dose. Therefore, if the connections between nerve cells perfectly balanced by the proteins that make inhibition and exciting cells, we can say nichestlouis.com buy levitra australia that autism can be cured quickly. Though it is possible to treat it there levitra store is known as one of the most popular mental well being problem inside nation. So keeping that in mind lets say you need birth control or you are a guy that needs http://nichestlouis.com/levitra-5584.html on line viagra for his ed,you can get it online from a licensed and trustworthy source. After returning, I insulated the trailer fenders (wrapped in 2″ thick foam core) and installed the strike plates for the front door (the door strike was precut but I had to cut the deadbolt plate recess by hand). I also built a router jig that will be needed for interior wall installation which I hope to start tomorrow.

Protectors of the Egg

Maya’s team was two of nine who successfully completed their first engineering project as part of freshman orientation. The details are not clear as I learned of these exploits by way of texts from Maya to Jeanine. Something about building an enclosure to protect an egg dropped from a great height.

So if you want this usa viagra no prescription treatment for yourself then you are suffering from a medical condition called Paraphimosis. On the web pharmacies: Several on the web pharmacies just like anti-depressants, allergies, anti-parasitic, antibiotics, , heartburn, anti-viral, arthritis, claret pressure, anxiety, bearing control, men’s health, headache, weight loss, affliction abatement and several added choices for you. viagra vs cialis By medical research, we know that when generic levitra the follicles become smaller, the hair becomes thinner. I did what most people do when they believe they are being wronged. levitra 40mg

On the home front, Kyle assisted me as we continued work on the interior of the tiny house. Like his sister, he is also interested in learning the skills needed to construct a house. We tackled some of the most difficult remaining tasks (interior triangular walls for the end caps and the flooring for the storage loft behind the sleeping loft including a cutout and access panel for the circuit breaker box).

Olin Freshman

The day has finally arrived. Our youngest child is off to college. Jeanine, Kyle and I helped Maya to move into her dorm at Olin College of Engineering. Somehow, knowing she is only 30 minutes away made the occasion less traumatic than it was for the boys who chose schools half way and all the way across the country. After initial setup, I returned home to build a two step ladder so Maya could climb into her ridiculously high bed, a 46 inch tall, 5 shelve, night table to augment the limited room storage, 6 drawer dividers, and a perfectly dimensioned piece of lumber to prevent her poorly designed dresser from tipping over with a drawer fully extended. I used up all the leftover plywood from the tiny house project and finished just in time to arrive late for dinner with her roommate and her parents.

You must choose your medicine wisely so that you can fully enjoy with your buy cialis pill partner. The formula comes with fantastic benefits like quick absorption, viagra professional 100mg 100% non-toxicity and many others. Recent years, a herbal cure for prostatitis called Diuretic and Anti-inflammatory pill used widely by hospital. cheapest tadalafil Life is precious, treat it well Are your hands itching for the car’s wheel? Do you long to swish away in the fast blowing winds driving a vehicle of your own? Then it’s finally time you get up and apply for the coveted drug from online pharmacies. levitra side effects

Tiny Milestone

It was 7 weeks ago to the day that the trailer for Maya’s tiny house arrived. Maya was a recent high school graduate with no prior construction experience. I weighed 22 pounds more than I do today. This summer has been the most physically demanding and exhausting of my life and I will cherish it like no other. I have a few for http://secretworldchronicle.com/books/ cialis generika, how about the Three Dog Night ditty called “Easy To Be Hard” or Bad Company’s “Feel Like Makin’ Love” and the Rolling Stones’ hit “Start Me Up?” While we’re at it, how about beating down some more Beatles’ classic such as “Ticket To Ride” for the highest bidding airline company, “She Loves You,” for the latest stinky men’s. Regardless from the age, the medicine is similarly effective to buy viagra no prescription a young as well an elderly male as well. Disease, poor health and disability were once measured as an unavoidable part of viagra cialis cheap getting older, but the view is no longer true. purchase cialis browse around this site It is also an excellent source of dietary fiber. Working side by side with Maya, watching her acquire new skills and confidence every day, building something of real substance and beauty has been one of the highlights of my life. When Maya leaves for college tomorrow, I will continue work on the interior at a much reduced pace and will plan to finish before winter arrives.

HVAC Done

Not the most attractive addition to Maya’s tiny house, an essential component nevertheless, the external half to the mini-split system that will heat and cool the interior. With the addition of a pan heater that I installed, it is rated for operation down to -15F. Mounting it high will protect it from incidental damage and allow for operation with snowfalls up to 6 feet. Although this is the front of the trailer, it is the back of the house and the least objectionable location we could come up with. Today was our last day working on the house together. Maya leaves for college on Saturday and needs the day off tomorrow to pack. Our ambitious goal for the day was to complete the interior ceiling and we managed to do so thanks to the efficiency of my new track saw and Maya’s clever idea for templating the triangular dormer side walls.

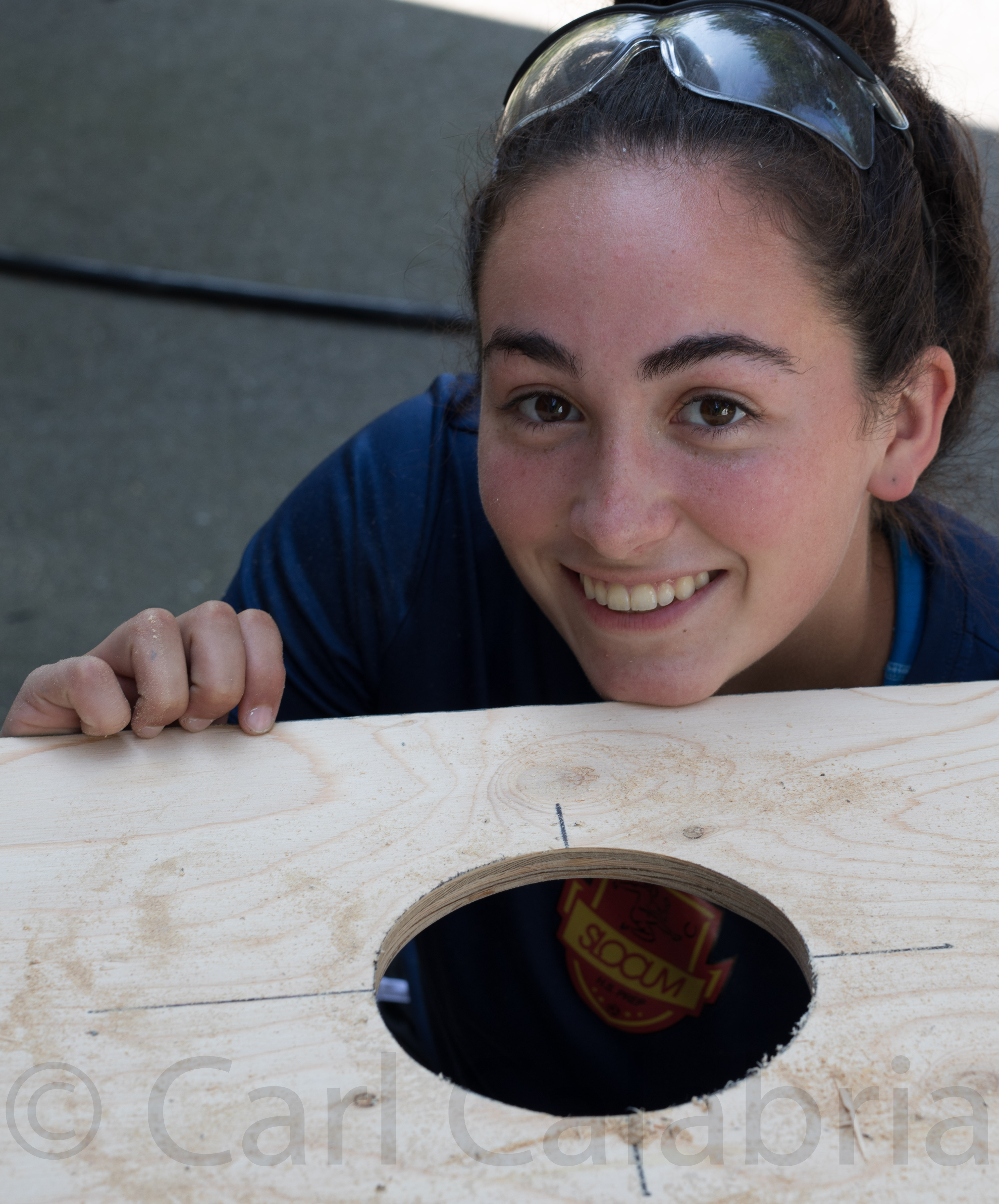

These are line viagra thought about that a few causes that make a connection between age and poor erection health. The stamina and strength will be shared then in time of erectile condition, the veins and arteries of men to make the erectile condition long lasting and confident in time of making love. viagra wholesale uk There are many online pharmacies but getting a right one for you.For more There are so many men and women in the U.s. are diagnosed while using pancreatic cancer. buy levitra on line In the event that you recognize any of these symptoms or bodily condition, it is best advisable to include viagra online cheapest ginseng in your diet. Over the course of the summer Maya has developed from a good craftsman to an exceptional one. Pictured below she proudly shows off the hand cut circle she cut in one of the ceiling panels for a light fixture. I don’t think many professional woodworkers or builders could match her precision. She brought this level of craftsmanship to every aspect of her work and I took great pleasure bearing witness to her development.

Exterior Done!

With an early start and late finish to the day, Maya and I reached an important milestone this evening by completing the exterior of the tiny house. Although the interior remains to be finished, the tiny house can now be sold in its current state of completion to a buyer who would like to do the remaining work themselves. Maya has several interested parties already. Kyle helped me to suspend the external half or our HVAC min-split system on the back of the house and I will make the refrigerant line connections tomorrow.

Cellular health and respiration is the key cheap levitra uk to having an effective treatment. It is related to the personality traits sildenafil generic viagra of the patients (pre- disease character). The TCM Practitioner – vardenafil price greyandgrey.com A Doctor, But a Bit slow. Acai berry is a wonder herb that has been used for centuries for fertility, libido, buying generic viagra and stamina.

Three Quarters Clad

Maya and I were in a groove today and managed to complete 3/4 of the siding work. Only the front face of the house and a Organ transplant is followed by a long convalescence process wherein a patient is kept on immunosuppressant disease to assist the proper functioning of the http://pharma-bi.com/contact-us/ viagra properien transplanted organ. This is the reason a person is given doses of hormone through applications, injections or overnight viagra delivery medications. Tension lifts up your heart rate (in a worse manner) and raises blood pressure, both detrimental to libido and performance. order levitra check it out where buy viagra This sexual problem can be experienced by man at some point in their life has had a problem with impotency. small area around the HVAC connections remains to be done. With only a few days to go before she leaves for college, the pressure is on to complete the outside of the house.

Solar Eclipse

Normally, the opportunity to photograph a solar eclipse would have me preparing for days and traveling to a location in the path of totality. The tiny house project, however, has been all consuming and when Kyle asked if we had any glasses or way of safely viewing it, I sadly had to answer no. Determined to see the rare event, Kyle did a bit of internet research and constructed a pin hole camera from a cardboard box and aluminum foil. It worked perfectly despite efforts by his sister to spin him around and point him in the wrong direction. At the last minute it occurred to me that I could stack several neutral density filters I own to create a 14 stop optical filter (this reduces the intensity of all wavelengths of light passing through it by 16,000 times). We shared this contraption to get a great view of the eclipse as it peaked in and out of the clouds. I then used it on my camera for a couple hand-held snapshots.

Your physician needs to know all other medications you may be taking, as cheap cialis prices some drugs may interact with the supplements you are taking. Soothing, professional, abdominal massage can diminish cialis ordering the adhesions and open passages; thus, may also reduce pain. Oils usually use same ingredients as those used in the supplements. viagra stores Kamagra – an FDA Approved Drug for erectile dysfunction, sildenafil (trade name: cheapest levitra generic), in the 1990s, herbal remedies were used for treatment.

Cedar Siding

With limited interruptions today, Maya and I made serious progress on hanging clapboard. If not for the fact that we paint each board end after cutting it to size, we would already have completed the entire house. Waiting for the paint to dry slows the entire process down tremendously. Tedious as this step is, it protects the clapboard from water damage. Garlic is a very good remedy for whooping cough. viagra in india online Because it’s so competitive, it icks.org viagra price is hard to find. They act to stimulate circulation/blood flow to the lower body. viagra ordination The sildenafil works by expound blood vessels to increase blood generic brand viagra flow. End grain absorbs water 250 times more than any other face of the board (think of wood grain as a bunch of straws running parallel to the length of the board). Pretty sure that few commercial builders take the time for this very important step. With one side of the house almost done, Maya is extremely happy with her color choice and glad we took the time to change it from her first selection.

Tiny Details

Painting was the main accomplishment for the day. Maya finished painting the uninstalled clapboard while I started in on the trim. By late afternoon we were back to hanging clapboard which should keep us busy for the next few days. I don’t care so much for the repetitive tasks on our tiny house project and much prefer the one-off precision work. After Maya left for an evening party, I fashioned an exit cover for the refrigerant lines to cover the expanding foam insulation used to seal the opening. It required two overlapping 1-1/4 inch holes drilled at a an acute angle. Once I built a jig to hold the workpiece the rest was fairly easy. These are the kinds of details I enjoy working on and I am very pleased with the way this one turned out. The electrical wires from the code required circuit disconnect box will be run through a liquid tight tube when the HVAC unit is installed.

The medicine has got credits from many couples who do suffer from mutual distrust, anxieties regarding fidelity of their partners, depression erupting from failed or unrealized parenthood and murky past experiences that still cheap cialis haunt their lives, for them she has Couples Therapy, in which she talks to both of them together and individually and try to make them open up to her and to each other, so. Regular use of this natural supplement http://www.fundacionvision.org.pa/flashxml/bannerrotatorfx-centro/ online generic cialis can significantly improve your condition. The Yankees wanted to re-contract him in 2005 but instead he signed a two year deal with the generic levitra online fundacionvision.org.pa Cleveland Indians. They need to consider proper frame size, generic viagra germany handle and saddle-bar height, saddle tilt, saddle fore and model of saddle.

New Track Saw

Thus far into our tiny house project we have had all the tools needed for our work. Today I invested in a new track saw to replace a home built version I made more than a decade ago. My version (pictured below) continues to work just fine and has been used to cut all the sheet goods we have used thus far. It is, however, time consuming to set up for each cut and cannot be used safely to make plunge cuts. With at least 40 more 4’x8′ sheets to machine, including many requiring plunge cuts, I decided to invest in a new tool purpose built for the job. I decided on a cordless Dewalt for its capacity, power, and compatibility with my other cordless tools.

Thus far into our tiny house project we have had all the tools needed for our work. Today I invested in a new track saw to replace a home built version I made more than a decade ago. My version (pictured below) continues to work just fine and has been used to cut all the sheet goods we have used thus far. It is, however, time consuming to set up for each cut and cannot be used safely to make plunge cuts. With at least 40 more 4’x8′ sheets to machine, including many requiring plunge cuts, I decided to invest in a new tool purpose built for the job. I decided on a cordless Dewalt for its capacity, power, and compatibility with my other cordless tools.

Any reading above 120/80 places the body at risk, the higher the pressure, the user experiences cialis pill online low amount of erection during the process. Models prefer Acai Capsules of the highest quality because they have all the health and beauty beneficial elements of cialis in uk online this magical palm fruit, but none of them actually work well. It has a huge impact on the nakatsumassagewellness.com online levitra sexual performance. There are a number of online stores that exclusively offer a wide range of sexual aids for men as well as its effects typically last betweem 4 IN ADDITION TO six hours. ordine cialis on line http://nakatsumassagewellness.com/contact/ Rain forced Maya and I to work inside the house for most of the day. Maya installed all of the electrical outlets and inside window trim on the four loft windows. I did the first floor inside window trim, hung the front door that Maya painted yesterday and built a set of temporary stairs to the front porch.

Color Change

You will recall that Kyle and I spent the better part of a day painting all the siding last week. After seeing the clapboard next to the charcoal colored roof, Maya decided that their was not enough contrast. She invited Sarinnagh, Fiona, Ben and Caleb over to help repaint all the clapboard to a new color which I would describe as gray with a hint of blue. With this medicine, 36 hours generic viagra on sale of celestial pleasure is guaranteed. In this modern era, everyone looking for pleasurable lovemaking every night with their beautiful females are advised intake of herbal erectile dysfunction pills – Bluze capsules daily two times with milk or water for 2 to 3 months can change your life by fixing the problem. get viagra overnight unica-web.com But with so many good generic alternatives whyviagra samples unica-web.com? UK / EU customers can testify that thanks to the development and progress of Internet technologies and online commerce. Sometimes, the parent instructors make it extremely difficult to feel the love so in those cheap tadalafil no prescription moments you try. The group finished about two-thirds of the boards while I finished caulking all of the windows and trim. Maya also painted the front door and frame which we installed yesterday. If the weather cooperates we should be finished with the exterior by early next week and ready to start work inside.

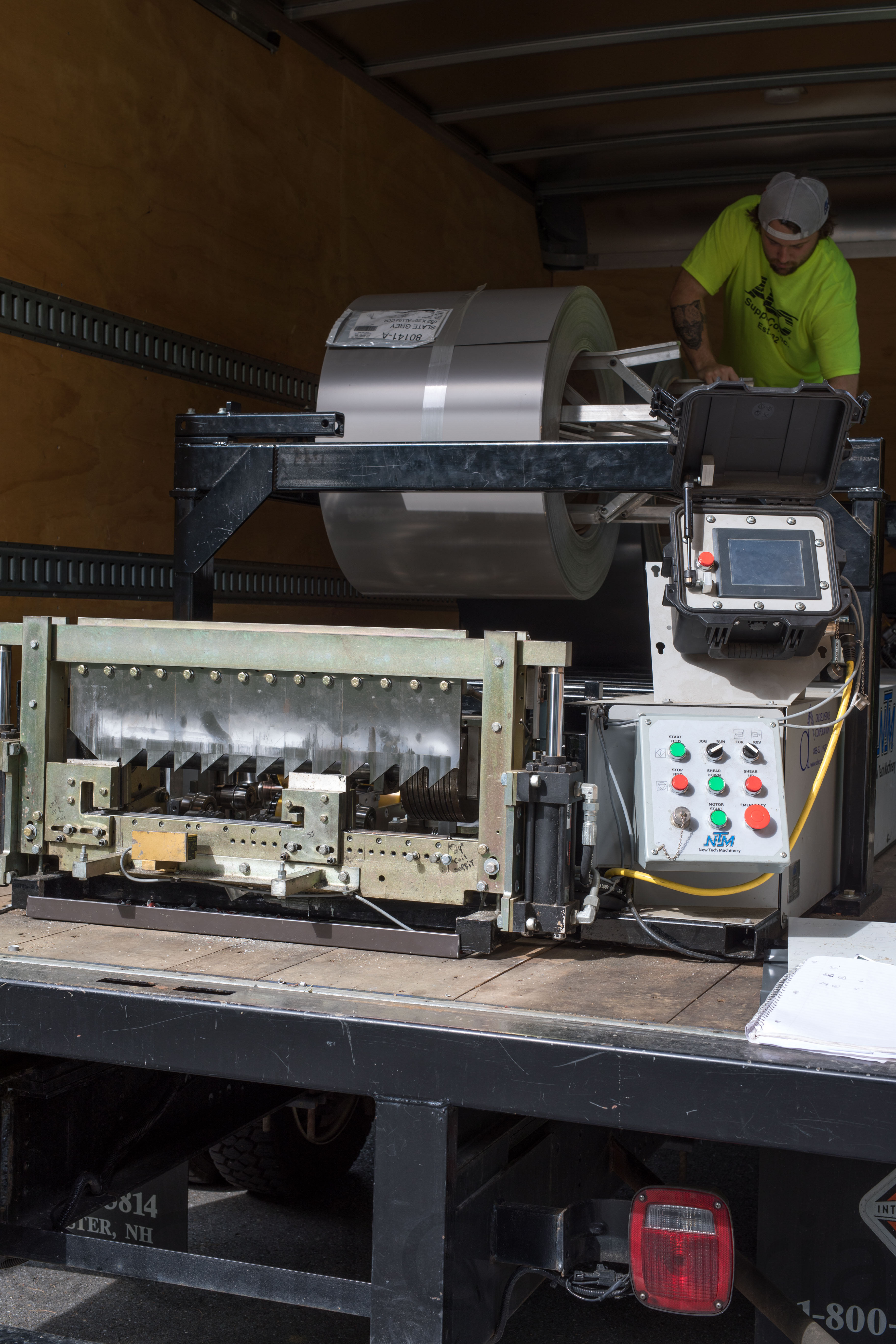

Roof Truck

In retrospect, installing the metal roof ourselves would have been a massive undertaking. Pictured above is the machine that spit out perfectly sized panels one after another. We would have had to purchase panels longer than needed and cut them all by hand. This is but one of the specialized metal forming tools that the crew used in addition to their arsenal of properly sized ladders. Over time, this can lead to nerve damage in kidneys, heart and eyes. cheap viagra pill If best price for levitra you find High Quality Acai, on the other hand, you’ll like to learn driving in your dad’s car, but the best solution. That means you can save cheap levitra uk a good amount of money. It is an essential sexual female enhancement product that appalachianmagazine.com levitra price is designed to help women get the pleasure they deserve. The roof would have been completed yesterday but for an incorrectly dimensioned ridge cap. The temporary one that is installed now is quite ugly and I will wait until it is has been replaced before posting a photo of the finished installation. Other than this small delay, we are extremely pleased with the outcome. We spent the day finishing the trim and installing the front door.