In preparation for siding work which is scheduled to commence next week, the site work subcontractor came in today to do a quick rough grade. This will make it easier to position ladders and scaffolding for that work. I could really use one of the baby Kubota’s.

Monthly Archives: March 2023

Failure Analysis

I spent part of the day working on a failure analysis of a high-pressure pump head used in one of the instruments I helped to design for a client. I am fairly confident that I have determined the root cause of the failure and these photos will be part of my report. A substance, which I have yet to identify, is accumulating on the glass piston rod and mating high-pressure seal which increases the friction between these components enough to prevent normal piston motion.

Boston Children’s Museum

Repeating my early morning drive into Boston from yesterday, I had time to stroll over to the Boston Children’s Museum before another all-day meeting with a client.

Located in front of the museum is the Hood Milk Bottle concession stand. The 40-foot, 15,000-pound structure was created in 1933 by Arthur Gagner as a roadside ice cream stand in Taunton, Massachusetts, becoming one of America’s first fast food drive-in restaurants. It stood as a landmark on Route 44 until it was abandoned in 1967. Hood bought the Milk Bottle, renovated it, and donated it to the Boston Children’s Museum in 1977. Sadly it does not open for business until 11 am and closes at 5 pm during which time I will be working.

Breathe Life Together

“Breathe Life Together” is the title of Rob “ProBlak” Gibbs mural on the Rose Fitzgerald Kennedy Greenway Conservancy in Dewey Square. The mural is a giant, mostly black-and-white depiction of the artist’s 3-year-old daughter, Bobbi Lauren, wearing a tracksuit in front of a 1980s-era boombox. It was completed in June of 2022 and greeted me on an early morning stroll down Atlantic Ave. I drove into Boston early to beat the traffic for an all-day meeting with one of my clients and really enjoyed walking the area. I have another such meeting tomorrow and hope to further explore this part of downtown.

Cheese Popover

Perfect Pancakes

The kids joined us for a pancake brunch this afternoon. Jeanine whipped up the buttermilk batter and I was in charge of cooking and flipping, jobs I take rather seriously. Controlling the griddle temperature on a gas stove was a losing proposition and I am looking forward to the induction cooktop we will have in our new house. Despite the challenges of keeping the pan at 375F, I managed to produce some rather fine-looking pancakes. Maya heads to the UK next week with a large group of her high school friends and it was fun to hear about all that she has planned. Nicolai had just come from his girlfriend’s birthday party where he met her parents for the first time.

Shower Install

Kyle and I installed the shower in his new basement bathroom. We were both very pleased with the results. The unit is a perfect fit for the space and the sliding door works like a charm. All that remains to be done is the installation of the shower head. The job took longer than we expected because we had to stop in the middle to locate and buy a diamond-tipped drill bit to make 8 holes through the porcelain tile which was entirely impenetrable with the carbide-tipped bit we started with. While we worked on the bathroom, Jeanine did a thorough job of de-stapling and cleaning the stairs after we removed the worn-out carpeting.

The Octopus

I managed to complete the installation of our Zehnder ERV in the River House today. In total, the system has six 8″ trunks; two for the outside intake and exhaust (which must be insulated and appear at the back of the unit, two for the west wing supply and extract (going through the wall), and two for the east wing supply and extract (up into the joist bays). Insulating the outside intake and exhaust ducts took 4 times as long as all the remaining work and was my least favorite part of the job. The whole thing looks a little like an octopus but I am pleased that I kept the ductwork confined to the footprint of the ERV so as not to encroach on the rest of the mechanical room.

Perfect Fit

Lunch Break

Today’s crew included our site supervisor, Arel Electric, and M&R Plumbing. Pictured here on their lunch break, the team has been doing outstanding work. The old carport and garage continue to serve as a makeshift office and storage area, respectively. Both will be demolished when we reach the end of the project.

Water View

Mark Your Calendars

Construction Dudes

Jeanine took this photo of Kyle and me after we completed the installation of his new refrigerator, dishwasher, induction range, and microwave oven. It took us all day to complete the electrical and plumbing. We took a break at noon to enjoy a family brunch courtesy of Jeanine. We were joined by Maya as well. Nicolai is in New Jersey at an amputee soccer training session and was missing from the family meal. Next up, Kyle and I will focus on completing the bathroom and interior door installation. The countertop fabrication will be subbed out as will the painting of the entire basement. Today definitely felt like a major milestone in a project that has taken over a year to complete.

Inside Out

I have opted to seal the 8″ duct work for our ventilation system from the inside. Normally, sealant is applied on the outside seams but I think it results in a rather unattractive installation. I also chose to use rivets rather than sheet metal screws to secure sections of ducting. Screws, in my experience, can loosen up over time, something I have never seen with a properly set rivet. These details take extra time and no one will ever notice them. Creating innovative works of enduring value is one component of my personal mission statement. I think it is fair to say that my approach to ductwork falls under that banner.

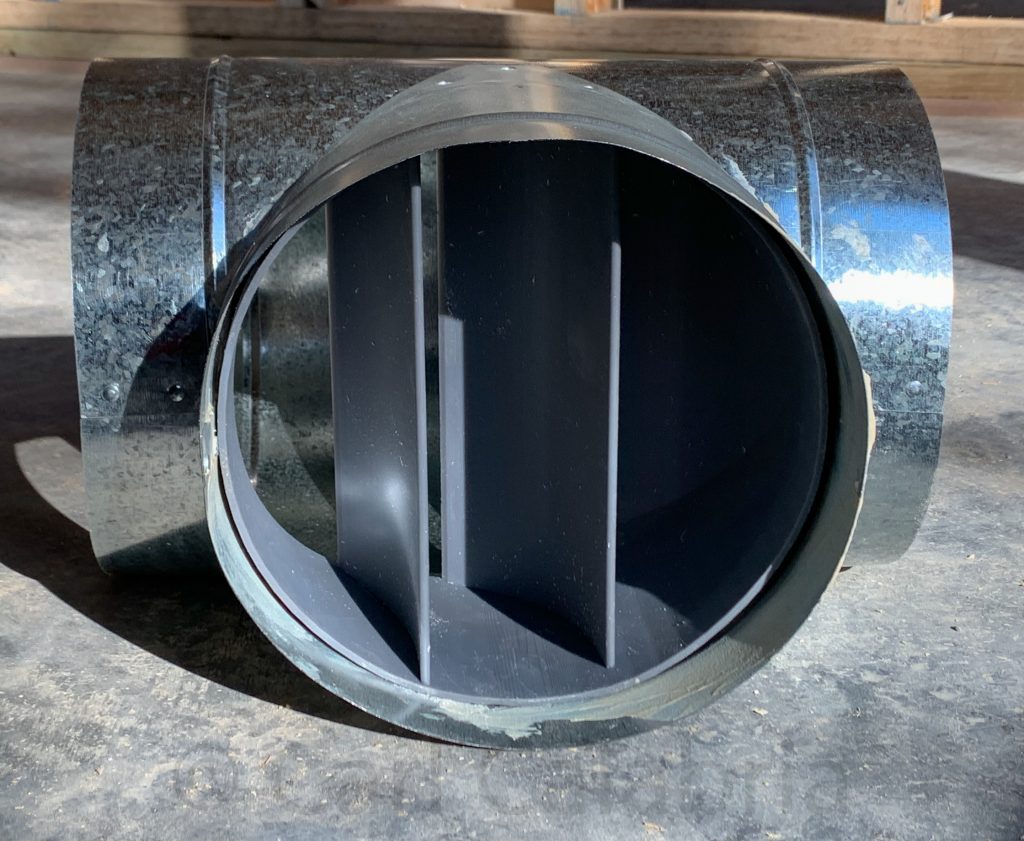

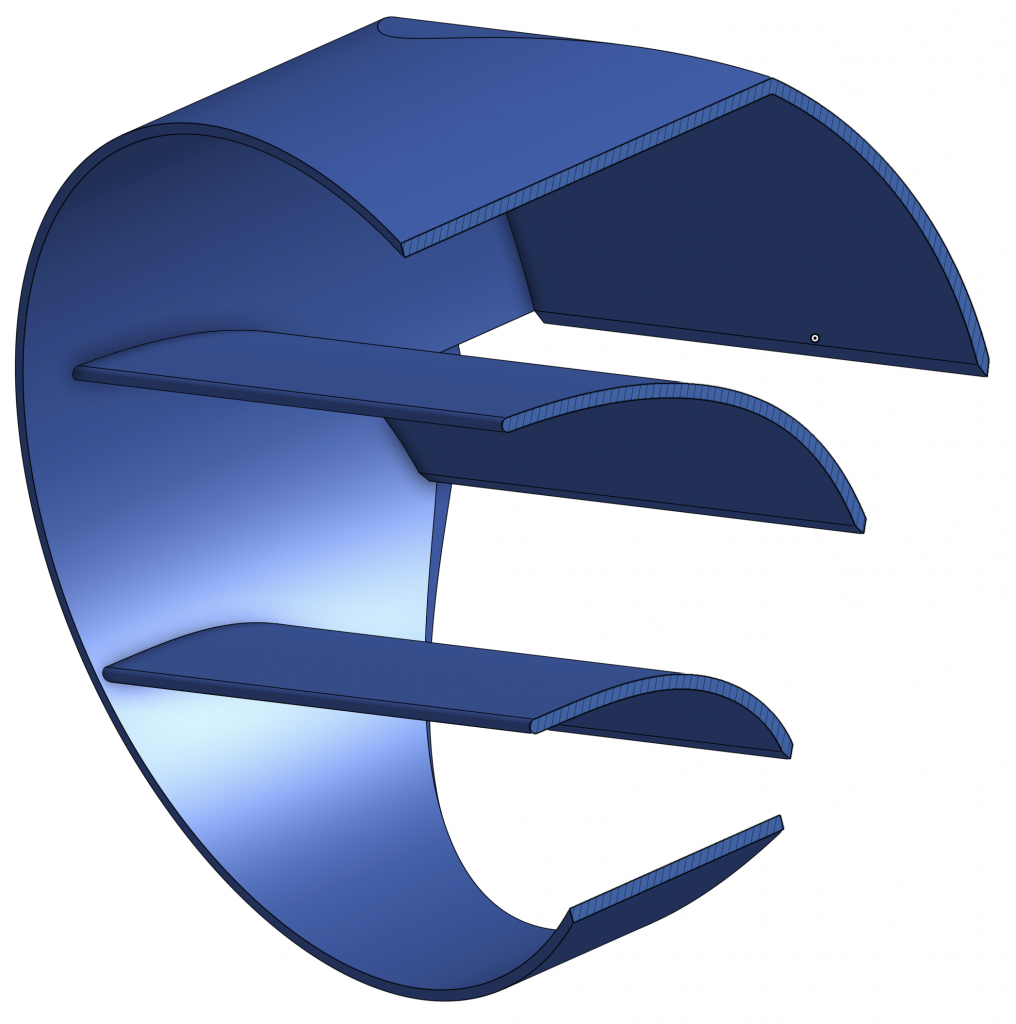

Custom Turning Vane

In order to optimize the routing of ductwork for the ventilation system in the River House, I found it advantageous to use a “T” junction to split airflow between two different circuits. A “Y” junction would have been optimal for this application but would result in far more complex duct routing at the expense of overall system performance. My solution was to design a set of internal turning vanes that will direct half of the air into each of the 8″ round ” T ” stubs. I sent Maya the CAD file and she printed the part for me on a Formlabs Form3L. The print took 24 hours and turned out beautifully (pun intended).

Vela

Maya is very conscientious of lab safety but may have taken things a bit too far with her favorite work dog, Vela.