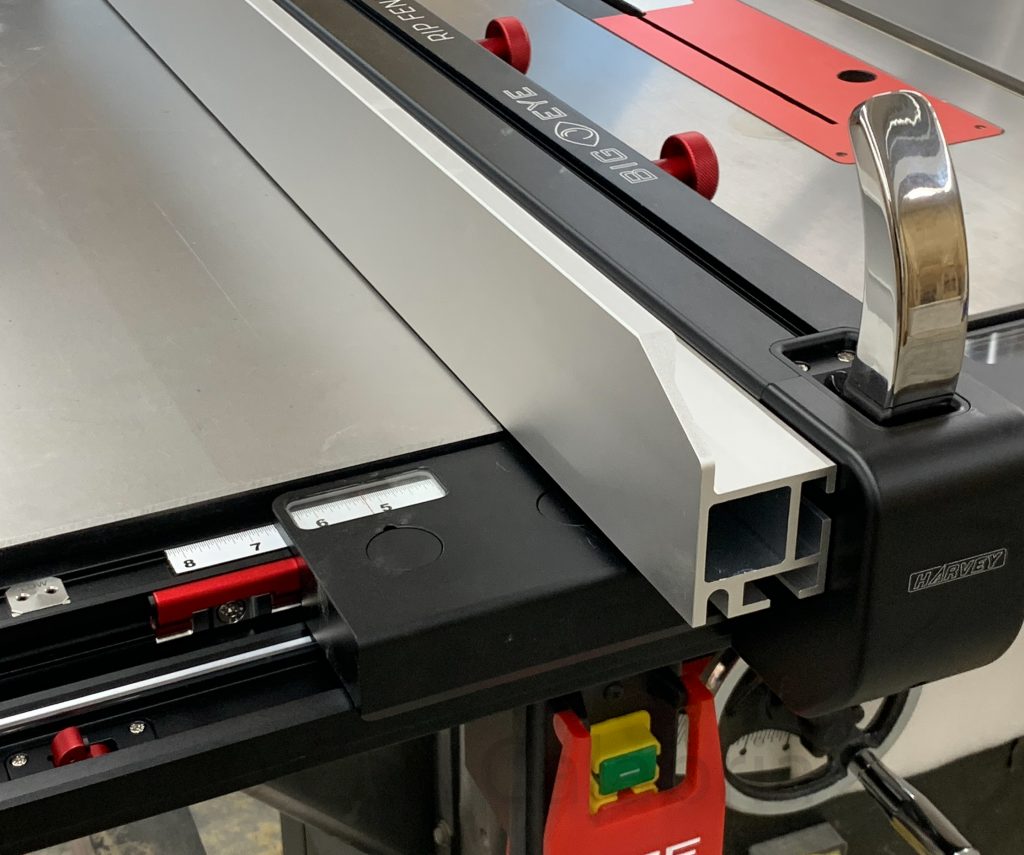

Pictured above are the angled ends of two 8-foot-long handrails. the first joint takes the diagonal rail back to horizontal and the second turns 90 degrees to mate with the Newell post. Each rail has 20 recessed holes on the underside angled at 32.5 degrees where the baluster will be situated. Each recess has a smaller and deeper hole drilled in the center where a 3D-printed baluster connector will be fastened with a screw. In total, each rail requires more than 60 machining operations and a dozen glue ups. A single mistake can render the entire rail unusable which makes for very stressful work. Fortunatley, these two rails came out perfectly and today they were treated to two coats of sealer and two of a protective finish. During the 2 hours of drying time between each coat, I installed a new fence on my table saw. I ordered the device back in September and have been patiently anticipating its arrival. All I can say, is that it was worth the wait and every penny I paid for it. I then cut down and fitted the original fence to my bandsaw and scrapping the piece of crap it was supplied with.